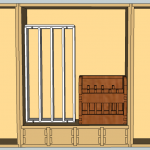

I got some time today to work on the hand tool cabinet, specifically starting on the hand plane storage. I am actually breaking from my sketch-up plan almost completely on this. Since I made the cabinet an inch deeper, I decided I could do a little better for my block planes. So I decided I would build a block plane garage. I had a few cut-offs that were left from the case construction, so they were wide enough, w4ithout glue-ups. I planed these down to 1/2″ thick, as I felt 3/4″ thick would be too much. After I planed them down, I ripped the stock to width, then cut each piece to length. At this phase, I wasn’t sure how many cubbies I would have (I was playing this by ear after all), so I made sure I cut what turned out to be one extra spacer. At this point, I glued everything together. Once the glue was dry, I did a base sanding to get everything good and smooth. On the router table, I routed round overs on the front. At this point, I noticed that it was sitting as flat as I would have liked. So I took my hand planes, and started planing down the bottom of the dividers, until I got sitting flat. From there I took a rasp and completed the round overs. Now this may seems like a minor detail, but it doesn’t take long, and it makes the piece look so much more refined. From there, I did the final sanding.

I got some time today to work on the hand tool cabinet, specifically starting on the hand plane storage. I am actually breaking from my sketch-up plan almost completely on this. Since I made the cabinet an inch deeper, I decided I could do a little better for my block planes. So I decided I would build a block plane garage. I had a few cut-offs that were left from the case construction, so they were wide enough, w4ithout glue-ups. I planed these down to 1/2″ thick, as I felt 3/4″ thick would be too much. After I planed them down, I ripped the stock to width, then cut each piece to length. At this phase, I wasn’t sure how many cubbies I would have (I was playing this by ear after all), so I made sure I cut what turned out to be one extra spacer. At this point, I glued everything together. Once the glue was dry, I did a base sanding to get everything good and smooth. On the router table, I routed round overs on the front. At this point, I noticed that it was sitting as flat as I would have liked. So I took my hand planes, and started planing down the bottom of the dividers, until I got sitting flat. From there I took a rasp and completed the round overs. Now this may seems like a minor detail, but it doesn’t take long, and it makes the piece look so much more refined. From there, I did the final sanding.

The next phase of plane storage will be the till for the bench planes. I haven’t 100% decided how the plane will turn out, I am thinking through some ideas. As soon as I come up with something, I will post here. I still have the doors to make for the cabinet. I figured out that I need more wood to completethem, so I haven’t started yet. My driveway the last few weekend has been inaccessible due to road work. My plan next weekend is to go to my hardwood supplier and get more so that I can start on the doors when I am ready for them.

The next phase of plane storage will be the till for the bench planes. I haven’t 100% decided how the plane will turn out, I am thinking through some ideas. As soon as I come up with something, I will post here. I still have the doors to make for the cabinet. I figured out that I need more wood to completethem, so I haven’t started yet. My driveway the last few weekend has been inaccessible due to road work. My plan next weekend is to go to my hardwood supplier and get more so that I can start on the doors when I am ready for them.